What We Do

Custom Solutions

Design, build, and implement opto-mechanical test and monitoring systems – especially integration into vacuum multilayer depositions systems.

services

Typcial services range from the design, construction, and implementation of mapping testers to integration of monitoring capabilities into existing process environments. Variations of these services are often adapted to customer-specific scenarios (e.g. in the Medical Devices industry)

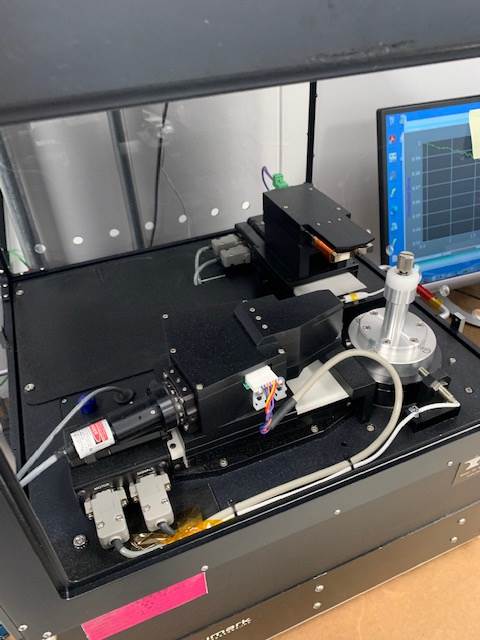

Magnetic Decay Tester

(Designed, built, and implemented in partnership with Jason Pressesky)

Monitoring

Passive monitoring of deposition processes using a wide range of optical probes and crystal monitor. These can be used for data collection and R&D for film growth at the interface between layers.

Process Control

Active monitoring typically involves orchestration of system-level hardware with data collected by an optical monitor (in reflection and/or transmission) and analyzed by third party thin-film optical analysis software. Alternative include use of a crystal monitor or a combination of crystal and optical monitors.

Metrology

Stand-alone test equipment designed to rapidly map performance across the surface of a test part. The displayed image to the right involves rotation of a test part and translation of optical probe/detection system. In this particular case a translation stage is also used to apply a pulsed magnetic field.